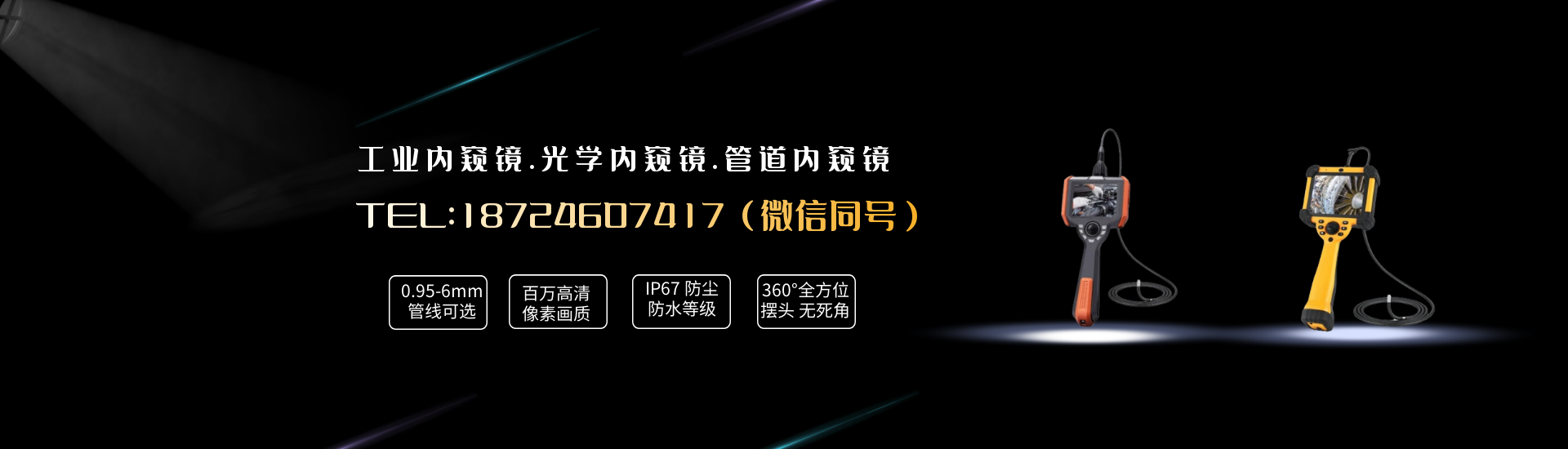

Industrial endoscopes nowadays have actually been made very detailed in terms of function, because there are many scenarios that need to be applied, and the special environments faced are also very much examined in terms of product performance;.

Even so, there are still many special monitoring environments that ordinary endoscopes can not do, such as monitoring the environment with corrosive liquids, pipeline area is abnormally narrow and so on, this situation can only be customized under the segmentation function of the endoscope brand, so that it can cope with the different special detection environments;

Then what special testing environment need to go for endoscope customization? Vitec's editorial is here to give you a specific explanation:

1, the detection of pipeline bend angle is particularly large, may need to turn several bends, in this case you need to customize 360 ° free rotation and the maximum range of vision borescope, in order to maximize to meet the conditions;

2, corrosive liquids in the monitoring environment, such an environment on the line pipe and probe material requirements are very high, to be sufficiently corrosion-resistant in order to complete the detection task; in this case in the pipeline material must do customization, in addition to change the pipeline;

3, endoscope price to have explosion-proof function, this not only need to insert the tube to customize the special material, even the host shell need to achieve customization, so as to fully meet this special monitoring environment;

4, endoscopic equipment pipeline needs to be resistant to high or low temperatures; currently on the market industrial endoscopic pipeline material in the temperature tolerance, can be controlled in the range of -40 ° ~ 85 ° or so, each manufacturer can be customized according to the detection of different environments and different material grades of endoscopic equipment;

5, the customization of the length of the pipeline, the longer the general length of the pipeline, the worse the degree of manipulation of bending, because it will be affected by the transmission process of the signal line, the distance to a certain extent will also affect the controllability of the probe;

In general, if you need a long distance pipeline to detect, more than ten meters then also need the probe 360 ° turn, which will need to determine the size of the pipeline diameter;

Many different features in the face of complex detection environment can be customized according to customer demand to achieve, relatively speaking, the flexibility is still very large, but also to meet the customization needs of many customers; such as customization needs, look for Witte Zhi Inspection, will be able to customize the endoscope products according to your different detection needs.