With the continuous development of the machinery manufacturing industry, quality management and production efficiency have become one of the most important concerns for manufacturers. In order to meet the market demand, manufacturers need to continuously carry out quality control and improvement in the production process. The industrial endoscope is an essential tool in this process.

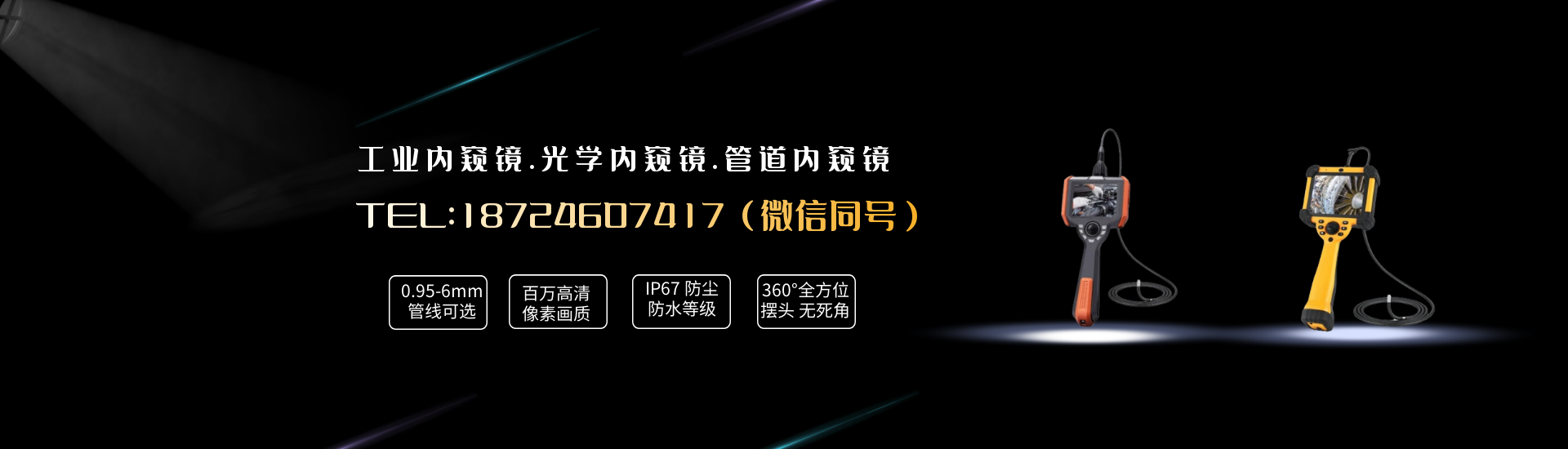

An industrial borescope is a small, optical device that can travel through hard-to-reach spaces and pipes. The borescope allows you to see into hard-to-reach places, so that potential problems in the production process can be identified and solved. Industrial borescopes can be used to monitor not only problems inside machines, but also the internal structure of pipes and other equipment.

For machine manufacturers, the use of industrial borescopes can improve productivity and quality levels. For example, borescopes can be used to check whether parts in a machine are correctly installed, avoiding failures due to improper installation. At the same time, industrial borescopes can also be used to monitor the lubrication of machines to avoid machine failures due to lack of lubrication.

In addition, industrial endoscopes can also be used to monitor the internal condition of pipelines. Pipelines are commonly used in the machinery manufacturing industry, but due to the complexity of the internal environment of pipelines, it is difficult to carry out inspection and maintenance. The use of industrial endoscopes can easily detect whether the internal structure of the pipeline is intact, avoiding problems such as pipeline blockage or leakage.

In short, industrial borescopes are indispensable tools in the machinery manufacturing industry. Through the use of endoscopes, manufacturers can find and solve potential problems in time, improve production efficiency and quality level, and finally gain market competitiveness.