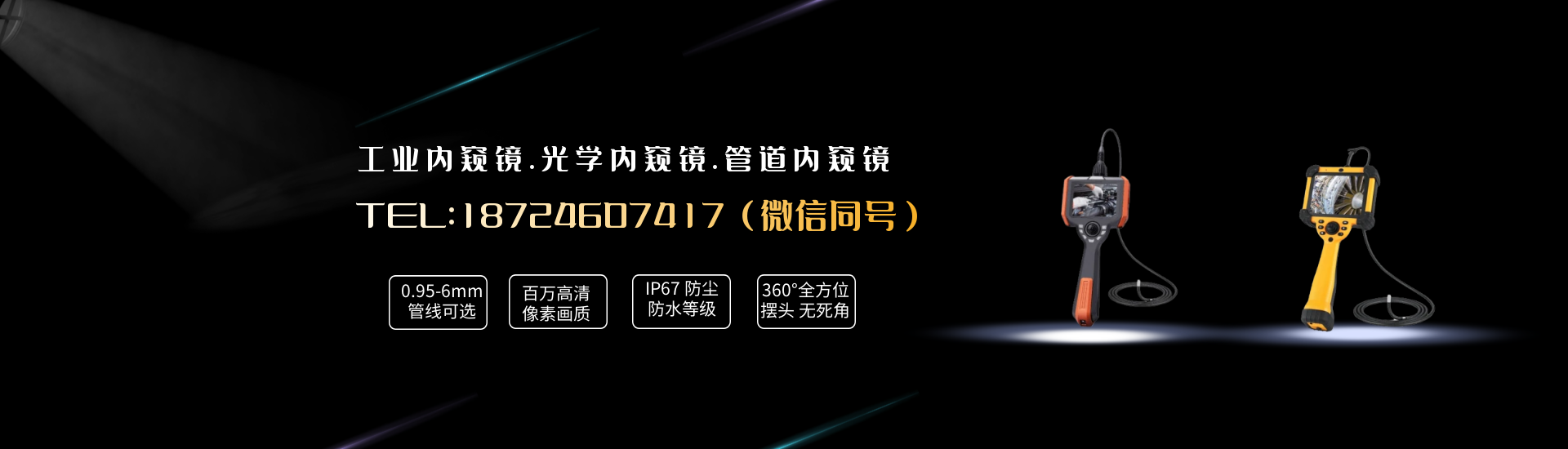

As people's demand for the quality of products and fittings continues to increase, the quality control of the weld has become an important barrier after the formation of products or fittings. In the face of the inside of the pipeline or difficult to reach the complex space to be inspected, the appropriate inspection technology and inspection means, can avoid the emergence of sub-optimal and defective products, for the enterprise to save huge economic losses and social impact. Direct visual inspection technology (RVI) is an effective means of checking whether the welding of steel, aluminum and titanium metal structures is complete; it can determine cracks, under-welded, slag entrapment, incomplete side-wall welds, leaks and other similar welding defects, hand-held industrial video borescopes can quickly and easily check the quality of weld surfaces, providing clear and complete storage of endoscopic images and video data; weld residue, weld channel quality and color, can all be lifelike.